Application of EPS crusher machine

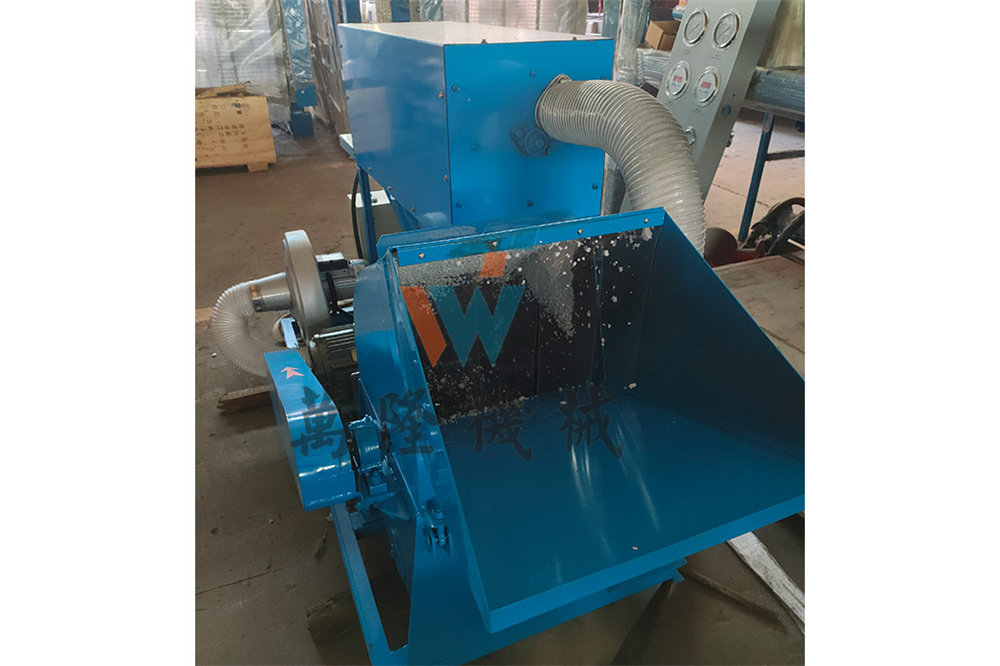

EPS crusher machine is one of the most popular machines in recent years. It is widely used in many fields, such as construction, decoration, packaging and so on. And it has many advantages, such as low noise, no pollution and so on. Today I will introduce you the application of EPS crusher machine in our daily life.

The EPS crusher machine can be used to crush EPS material into small pieces. And then these small pieces can be used for construction, decoration or packaging. For example, if you want to make some small crafts, you can use EPS crusher machine to crush EPS material into small pieces and then glue them together. Or if you want to pack something, you can also use EPS crusher machine to crush EPS material into small pieces and then put them into the box.

EPS crusher machine is a waste recycling equipment which can be used to process EPS waste into useful products. The processed products can be used as raw materials for various purposes such as manufacturing of new products, or they can be recycled back into EPS products.

How to maintain EPS crusher machine

The EPS crusher machine is a common type of machine used in the EPS industry. As with any type of machinery, it is important to maintain the EPS crusher machine on a regular basis. There are a few things that you can do to help keep your EPS crusher machine running smoothly.

First, make sure that you always use the proper lubricant on the EPS crusher machine. This will help to prolong the life of the machine and keep it running smoothly.

Second, be sure to clean the EPS crusher machine on a regular basis. This will help to remove any build-up that may occur over time.

Third, be sure to check the EPS crusher machine for any wear or tear on a regular basis. This will help to prevent any major problems from occurring down the road.

By following these simple tips, you can help to prolong the life of your EPS crusher machine and keep it running smoothly for years to come.

Common problems and solutions of EPS crusher machine

1. Overheating of EPS crusher machine

The main reason for the high temperature of the EPS crusher machine is that the air-cooled radiator cannot work properly or there is something wrong with the water circulation system. The solution is to check whether the water pump and radiator are working properly, and whether there is enough water in the system. In addition, pay attention to the cooling water inlet and outlet pipes to see if they are blocked.

2. Vibration of EPS crusher machine

The vibration of EPS crusher machine is mainly caused by loose parts. The solution is to check all fasteners and make sure they are tightened. In addition, check whether there is any debris stuck in the crushing chamber or near the motor, which may cause vibration.

3. Noisy operation of EPS crusher machine

If the EPS crusher machine makes a lot of noise during operation, it may be because the crushing chamber is seriously worn or there are foreign objects entering the crushing chamber. The solution is to replace the wearing parts in time or remove the foreign objects from the crushing chamber.