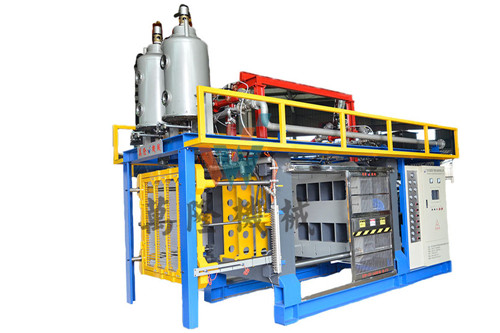

Mould adjustable eps block moulding machine features and usage

Mould adjustable eps block moulding machine features and usage

Mould adjustable eps block moulding machine features

1) mould adjustable eps block moulding machine has good energy-saving characteristics. Using the main steam proportional pressure reducing valve technology, it can be precisely controlled, and the steam pressure delivered by the main pipeline is more stable. Compared with similar equipment, the heating time can be reduced by 20% and the energy consumption can be reduced by 30%.

2) The mould adjustable eps block moulding machine has a simple structure. The design with stronger stability and better strength greatly improves the strength value of the machine. The template can be annealed at high temperature and processed by CNC center. On the one hand, high precision can be guaranteed, and on the other hand, the service life of the machine can be greatly extended.

3) The mould adjustable eps block moulding machine also has a special cooling system. This system is very important, mainly using high-efficiency vacuum system technology with low energy consumption. The large three-dimensional spray vacuum condenser is sprayed by the cooling water source to improve the vacuum condensation ratio, effectively protect the vacuum pump, and leave the intermediate vacuum interface in advance.

4) The control of mould adjustable eps block moulding machine is also very simple. Mainly through the touch screen operation. The way of operation is simple. At the same time, it also has an alarm system, which can protect the operator more systematically.

How to use mould adjustable eps block moulding machine

1. If you choose a flat plate and place the machine smoothly, you can pull the chassis feet apart to make the machine panel easy to observe.

2. Insert the plug on the hand-held sensor into the socket on the panel and tighten it. Note the positioning gap.

3. Insert one end of the power cord plug into the socket on the back panel of the chassis, and the other end into the power socket. Be sure to use a single-phase three-wire power supply.

4. Turn on the "power switch" on the rear panel of the chassis, and press the "Switch" button on the panel. When the "preheat" green indicator light is on, the machine can work.

5. Press and hold the "Set Button" key to set it to an appropriate value, generally between 0.5-2.0 seconds.

6. Place the sensor head on the container lid and press the start button on the handle. At this time, the "heating" red indicator light is on, indicating that the sensor head is heating. Do not move the sensor head. When the "heating" red indicator light is off, remove the sensor head, wait for the "heating" after the green indicator light is on or the buzzer in the machine sounds for a short time, and then the next container can be sealed.

7. Check the sealing quality. According to different materials, container diameters and production efficiency, properly repair the "set button" key to achieve the sealing quality.

Chinese plastics processing enterprises are all over China, and the technical level of equipment is uneven. Most processing enterprises need technological transformation. In recent years, China's plastics machinery industry has made significant technological progress, especially the technical level of mould adjustable eps block moulding machine and foreign well-known brand products have greatly narrowed the gap, and the control level, product internal quality, and appearance have been significantly improved.

About Wanlong Machinery:

Hangzhou Fuyang Wanlong Machinery Co., Ltd established in 1997, is a professional high-tech EPS (Expandable polystyrene) machinery & Mould manufacturer integrating R & D, production, sales and service. We have strong product design and innovation capabilities, with more than 10 of the provincial high-tech products, the invention patent, utility model and appearance design patent etc. In addition, we passed the certifications of quality management system ISO9001, the products has with high efficiency, low energy consumption, stability, durability, easy maintenance, etc.