-

Ceiling Cornic4

-

Ceiling Cornic3

-

Ceiling Cornic2

Ceiling Cornic

Port: Hangzhou, China

Production capacity: 30 pieces / month

Payment method: Letter of credit, telegraphic transfer

Mould Cavity: Customerize

Plastic Material: EPS

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

EPS ceiling polystyrene cornice moulding machine | cornice moulding machine | moulding machine

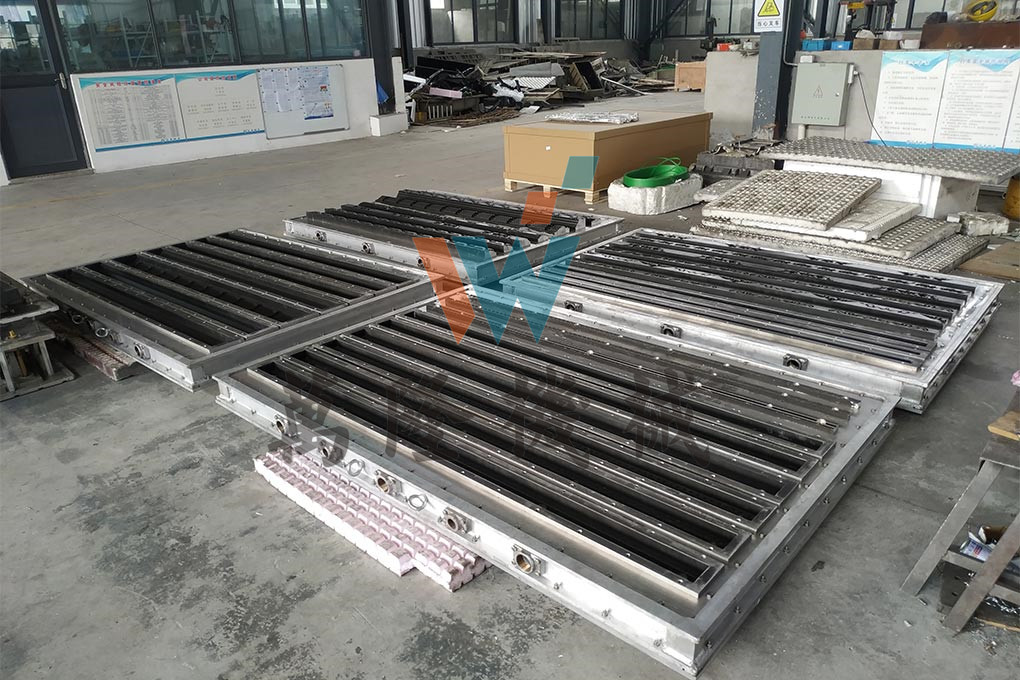

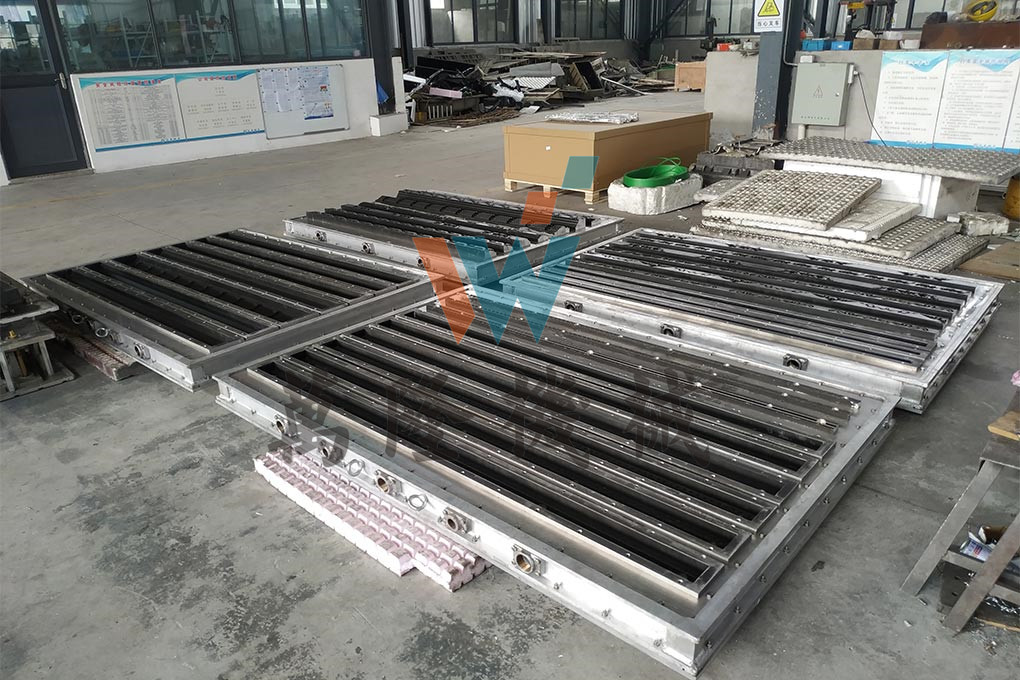

Mould department is a professional EPS (expanded polystyrene) mould manufacturer, was established in 1998. The capacity for annual producing moulds exceeds 200 sets mainly used in electrical appliance industry, aquaculture industry, construction and lost foam casting industries. High quality aluminum alloy material is used in all kinds of EPS moulds. The mould surface is spayed with protective Teflon coating with feature of excellent lubrication, no sticking of the product on the mould, convenient de-mould, good anticorrosion, resistant of high-temperature above 350℃,and long service life etc.

Wanlong has a professional and experienced mold designing, manufacturing team, and using CAD/UG/SolidWorks software for product and mould 3D design as per client’s information provided such as data, idea, sample, 2D drawing or 3D drawing. Using expert evaluation system and CAE analyze to optimize mould structure. In the production process, all the procedures are subjected to ISO9001 quality-control management system in providing a solid guarantee for high-product quality.

We have been cooperating with many providers of well-know companies in domestic market for years, such as Haier, Philips, LG, Gree, Mengniu, etc. also exported to abroad including

European, Africa, America, Middle East, Australia, etc.

About EPS ceiling polystyrene cornice moulding machine

Features:

1.Vacuum adsorption and dust collection system: vacuum adsorption table, adopted bakelite table, high density, no deformation and high adsorption, can for different size materials adsorption, saving time compared the traditional mechanical plate fixing, the vacuum pump can choose oil-less vacuum pump to solve water cooling vacuum pump changing water issue in the frigid weather; Dust collector helps to suck the dust, milling dust, saw dust during processing, keeping the working table cleaning and ensuring the machine long time using.

2.Advanced files pre-reading and verifying function. Mistakes in G code files can be corrected timely.

3. With the function of break-point memory ,power failure resuming and automatic home/origin correction function, effectively ensure long time working precision.

WANLONG MACHINERY is a leading EPS ceiling polystyrene cornice moulding machine supplier, factory, manufacturer that focuses on EPS ceiling polystyrene cornice moulding machine. Complete specifications and high quality. We are committed to treating customers with integrity and quality, thus winning a group of loyal customers.

EPS ceiling polystyrene cornice moulding machine

Our products are exported to dozens of countries and regions.