-

PLC MITSUBISHI

-

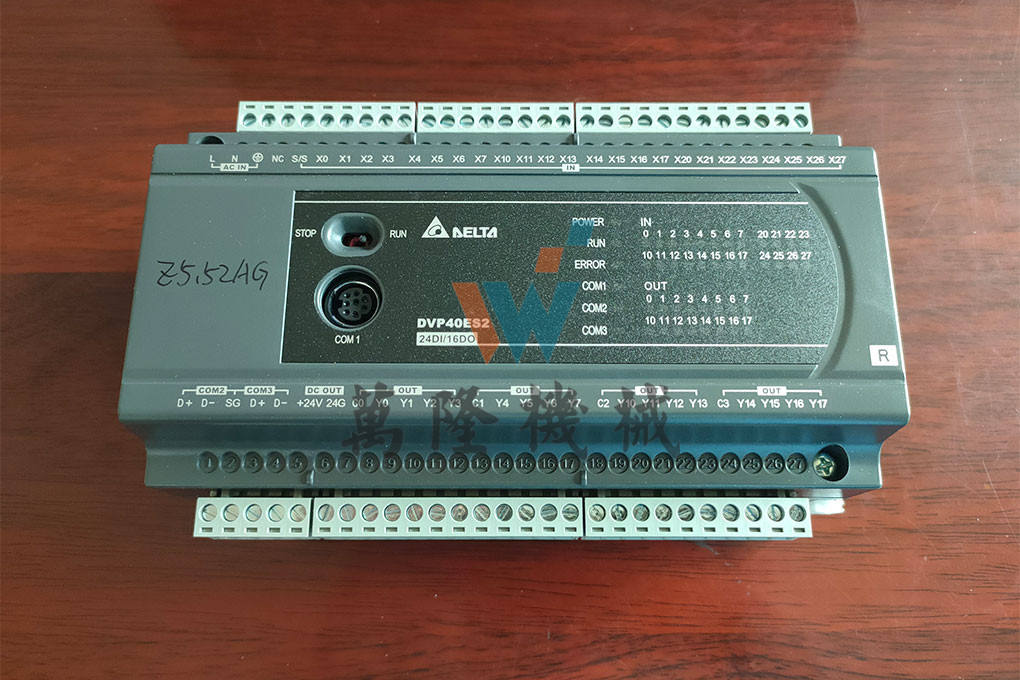

PLC DELTA

-

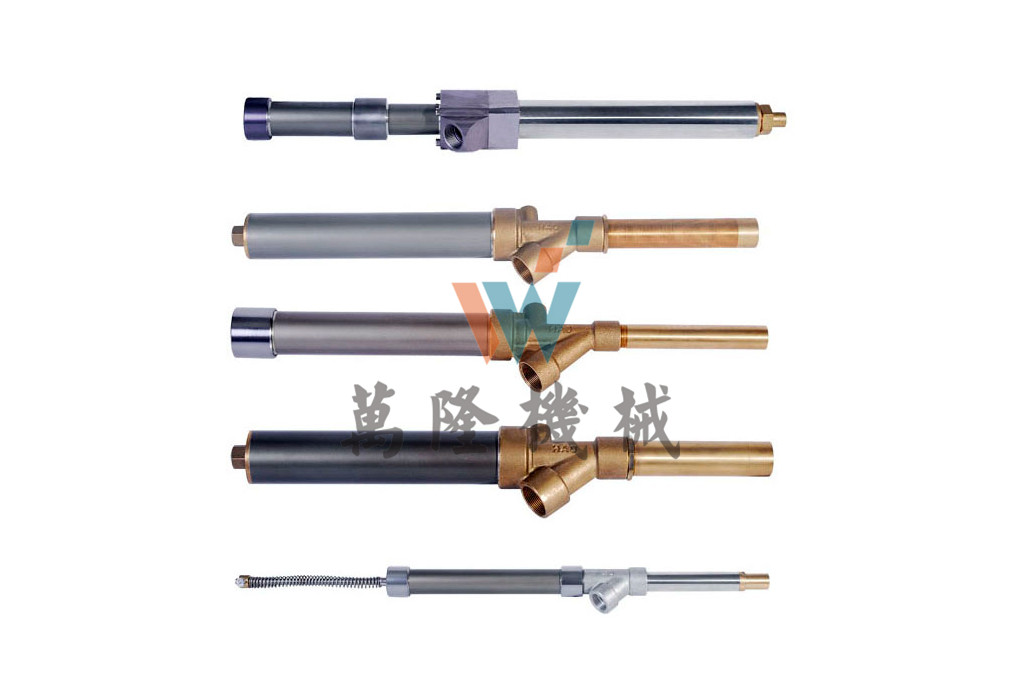

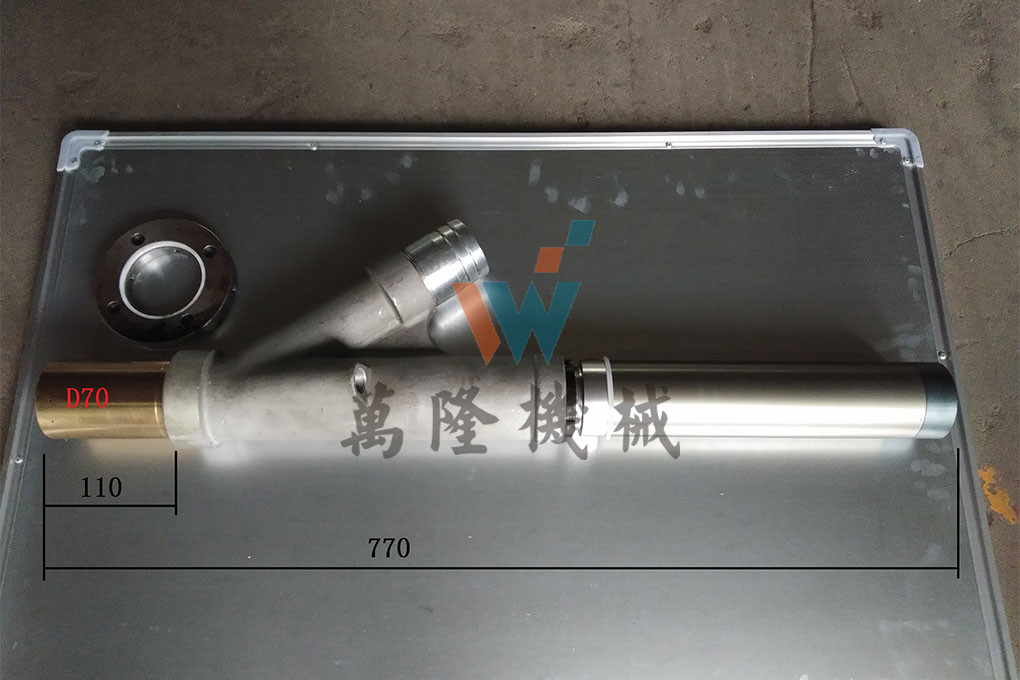

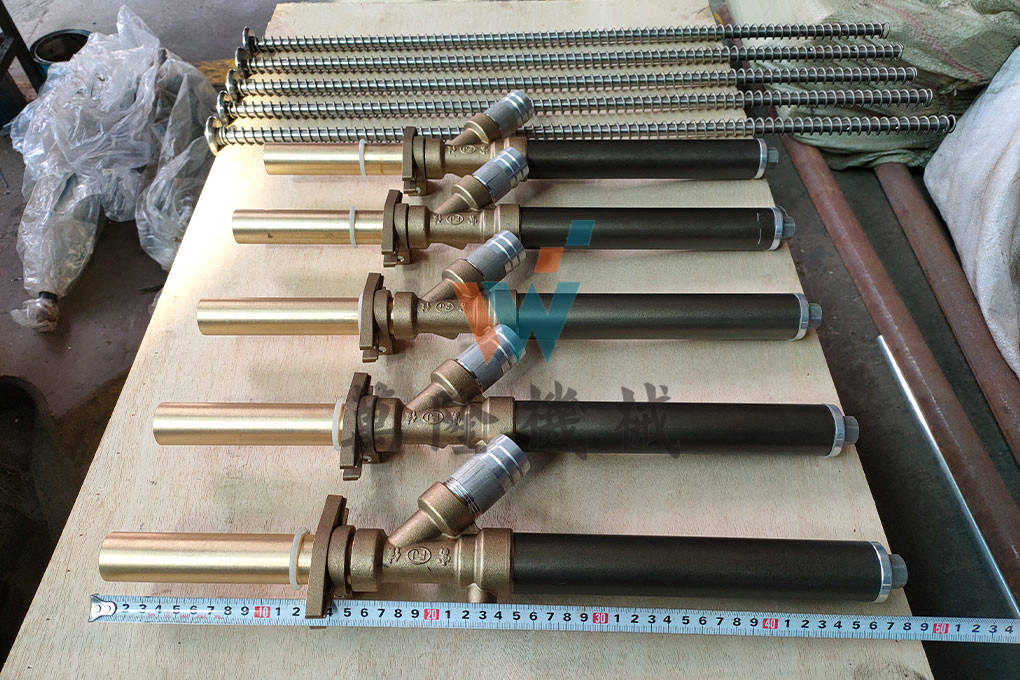

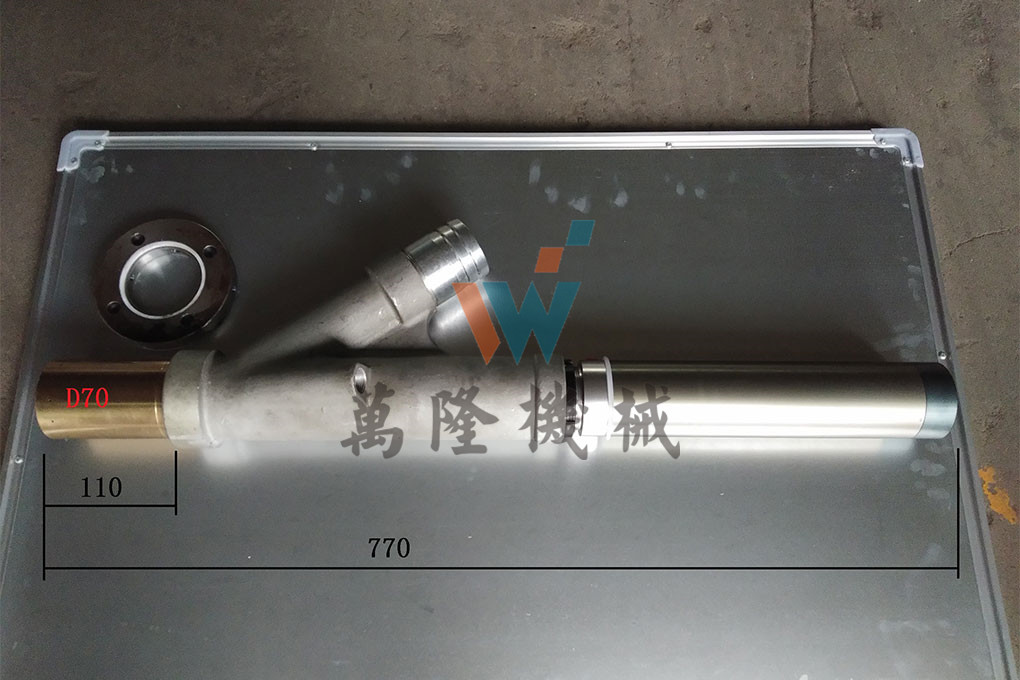

Filling gun for block moulding machine

-

Touch screen delta

Filling gun

Port: Hangzhou, China

Production capacity: 3000 pieces / month

Payment method: Letter of credit, telegraphic transfer

Mould Cavity: Customerize

Plastic Material: EPS

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

Polystyrene cornice moulding machine | moulding machine | cornice moulding machine

Supporting special silicone gun

Feel good, durable Usage: first with the thumb to suppress the back-end metal, pull the hook with the wire back, try to pull in place, first put the glass plastic head (with a mouth on the other end), so that the front exposed plastic mouth Part, and then the whole plug into the rubber, relax the thumb part, then squeeze on it

Usage: first with the thumb to suppress the back-end metal sheet, pull the hook with the next wire, try to pull in place, first put the glass plastic head (with a mouth on the other end), so that the front exposed plastic mouth part, Stick into the rubber, relax the thumb part, then squeeze on it

Our Advantages

OEM Service : Customers simply provide heat transfer, flow, inlet temperature, outlet temperature, operating pressure, resistance, heat balance, core body size and other relevant parameters.

Team Support : Professional design team and technology team provide 24 hours service and 12 months warranty.

Factory Support : Accept sample order, economical and practical.

More service

1) We can help buyers design specific products or produce products according to buyers'design.

2) We can print logo according to buyers' requirement.

3) One year's warranty against B/L loading date. If you meet with quality problem, we promise to replace goods.

About Polystyrene cornice moulding machine

Features:

1.Japan Yaskawa 850W servo motor and driver for XYZ-axis, ensuring the processing speed & precision.

2. 4 axis SYNTEC 6MB control system with industrial control system and hand wheel, safe and reliable operation, efficient speed to read the code, and have the online analog functions, on-line monitoring function to ensure efficient and safe processing.

3. Adopted the advanced Linear ATC system which can change 12 pieces tools intelligently. Tools changing time is within 10 seconds greatly improved production efficiency.

WANLONG MACHINERY is a leading Polystyrene cornice moulding machine supplier, factory, manufacturer that focuses on Polystyrene cornice moulding machine. We focus on producing high-quality products with complete specifications. The quality of our products has passed international certification and the price is affordable.

Polystyrene cornice moulding machine

When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.