-

PLC MITSUBISHI

-

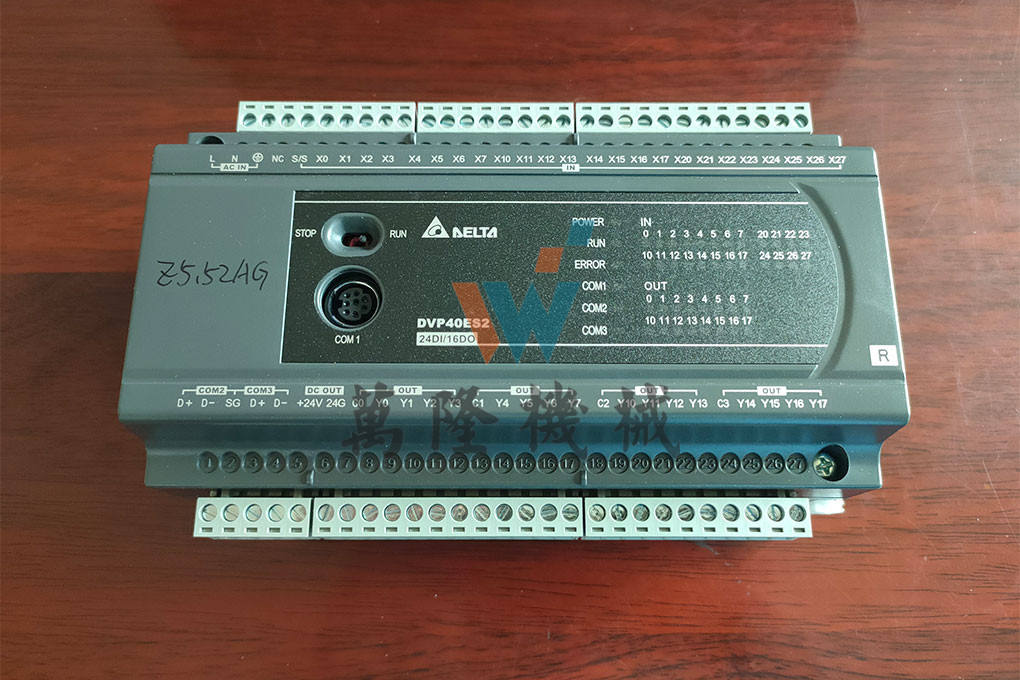

PLC DELTA

-

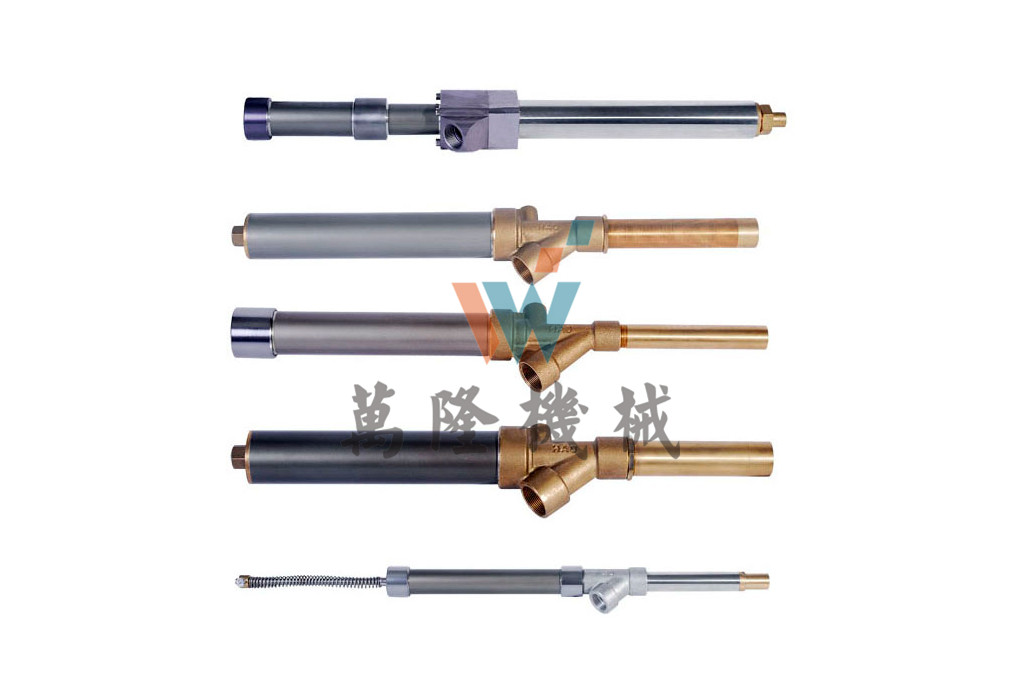

Filling gun

-

Touch screen delta

-

EPS polystyrene foam beeds machine

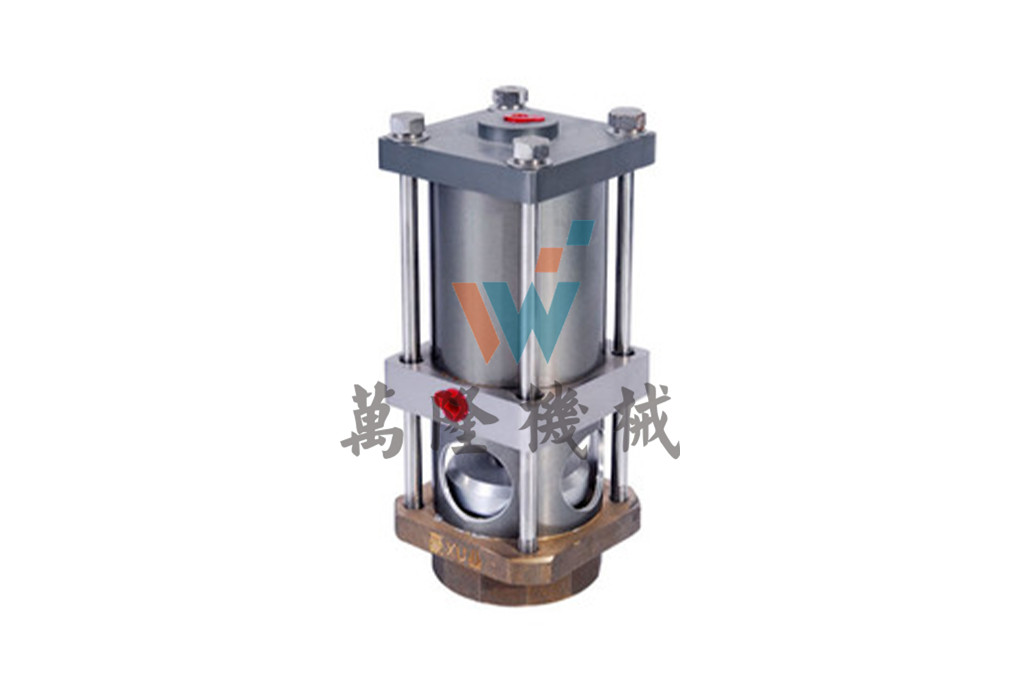

Solenoid valve

Port: Hangzhou, China

Production capacity: 3000 pieces / month

Payment method: Letter of credit, telegraphic transfer

Mould Cavity: Customerize

Plastic Material: EPS

Certification: CE, ISO9001:2008

Condition: New

Add To Basket

Add To Basket

PDF:

EPS polystyrene vacuum block moulding machine | vacuum block moulding machine | moulding machine

1. Only 25 Psi Can Start the Pneumatic Valve, Which is Easy to Operate, Easy to Install and Easy to Remove.

2. The Manual Button Tests the Status of the Product when It is Powered Up.two Air Intake Holes Cannot Be Used at the Same Time. when Using, You Need to Block One Side with a Plug.

3. The Valve Body is Made of High Precision Aluminum with High Hardness and Long Service Life.

4. The Inner Hole is Machined by a Special Process, with Low Frictional Resistance, Low Starting Air Pressure.

5. Please Pay Attention to the Direction of Gas Flow and the Correct Connection when Installing. Pay Attention to Dustproof. It is Recommended to Install a Muffler on the Exhaust Port.

6. Air Solenoid Valve Has Single Control Solenoid Valve Has Internal Pilot Structure, Sliding Column Structure, Good Sealing and Responsive.

7. Each Thread is Finely Processed, No Burrs, Smooth and Easy to Install.

8. The Valve Body Contains a High Concentricity Seal Ring, Which is Not Easy to Leak, and the Rubber Pad with Lubricating Oil Reduces Friction.

9. Each Product Comes with Fittings That Can Be Used Directly. No Need to Buy Additional Accessories, Just Insert 6mm or 1/4"tube.

10. Manual Operation, Smooth Operation, Accurate and Reliable Positioning. High Precision Stem Fit Degree is High Air Tightness.

11. Widely, Informs the Control of the Flow of Various Types of Fluids to the As Air, Water, Mud, Liquid Metals, Etc.

Our Advantages

OEM Service : Customers simply provide heat transfer, flow, inlet temperature, outlet temperature, operating pressure, resistance, heat balance, core body size and other relevant parameters.

Team Support : Professional design team and technology team provide 24 hours service and 12 months warranty.

Factory Support : Accept sample order, economical and practical.

More service

1) We can help buyers design specific products or produce products according to buyers'design.

2) We can print logo according to buyers' requirement.

3) One year's warranty against B/L loading date. If you meet with quality problem, we promise to replace goods.

About EPS polystyrene vacuum block moulding machine

Features:

1.Japan Shimpo Reducer for servo motor, used for replace traditional rack and belt,to make machine more powerful and stable.

2. 4 axis SYNTEC 6MB control system with industrial control system and hand wheel, safe and reliable operation, efficient speed to read the code, and have the online analog functions, on-line monitoring function to ensure efficient and safe processing.

WANLONG MACHINERY is a leading factory that focuses on EPS polystyrene vacuum block moulding machine. We solemnly promise to provide your products with excellent quality, reasonable prices and the highest cost performance.

EPS polystyrene vacuum block moulding machine

The quality of our products has passed international certification and the price is affordable.