A Simple Guide to Foam Cutter

A Simple Guide to Foam Cutter

Foam cutters are the perfect tool for cutting and shaping foam into whatever shapes and sizes you require. Whether you’re looking to make a model aircraft or a costume prop, foam cutters are incredibly versatile tools that can help you get the job done quickly and efficiently. But before you start using one of these tools, it’s important to understand how they work and how to use them correctly.

This guide will provide a simple overview of foam cutter basics so that you can get started with your projects right away.

First, let's take a look at the types of foam cutters available on the market. There are two main types: hot wire and motorized cutters. Hot wire cutters use an electrically-heated wire that melts through the foam as it is moved along its surface. Motorized cutters, on the other hand, use blades or rotary bits to slice through thick foams with precision and speed.

Foam cutters are incredibly useful tools that can help you quickly and accurately cut through foam materials. But like any tool, they require regular maintenance to ensure they continue to work at their best. With a few simple steps, you can keep your foam cutter in great condition and get the most out of it.

Next, lubricate all moving parts on a regular basis with a light oil or silicone spray. This will help keep everything running smoothly and reduce wear and tear on your machine over time. Additionally, always take care when removing the blade as it’s very sharp and can easily cause injury if handled improperly.

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

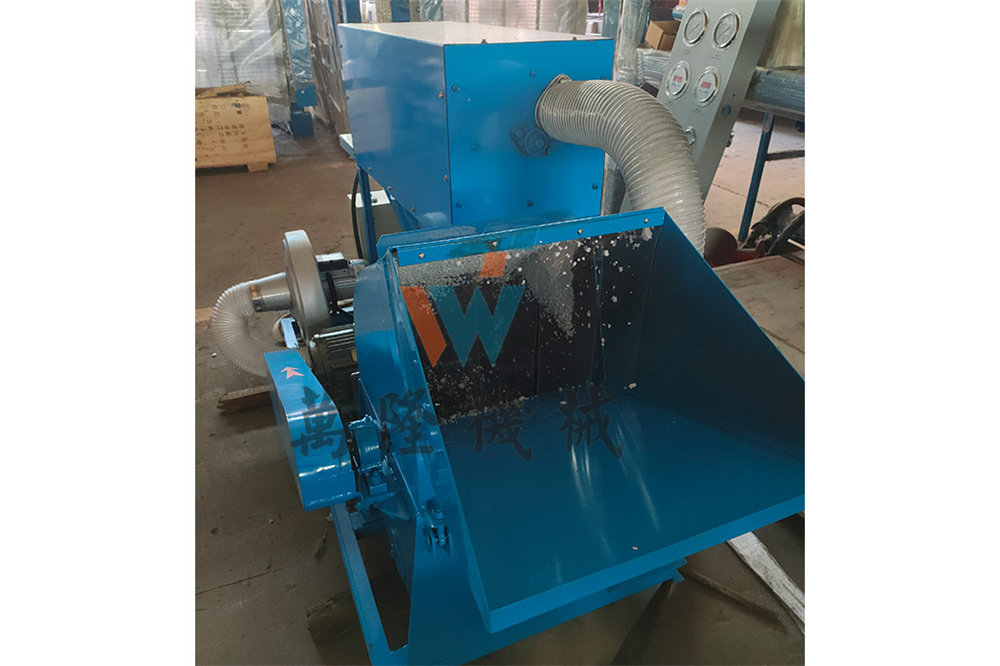

Crusher machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

EPS crusher de-dust machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Crusher de-dust machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Polystyrene crusher machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Grinder machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Eps Foam Recycling Machine

-

Port: Hangzhou, China

Production capacity: 20 sets / month

Payment method: Letter of credit, telegraphic transfer

Model:Automation

Computerized: Computerized

Certification: CE, ISO9001:2008

Condition: New

Foam Recycling Machine

-

How Foam Cutters Work

Foam cutters are tools used to cut foam into different shapes and sizes with precision. These tools come in a variety of sizes and designs, but the most common type is a hot wire foam cutter. This type of cutter uses an electrically heated wire to melt through foam quickly and accurately.

Hot wire foam cutters have a few components: the power supply, the wire feeder, and the cutting arm. The power supply sends electricity through the feeder which then sends it to a metal wire. The cutting arm holds this wire in place while it’s heated up by electricity. Once it’s hot enough, you can use it to melt through or slice through pieces of foam with ease.

These types of cutters are great for precise cuts because they make almost no mess at all. You simply hold your piece of foam against the cutting arm and guide the heated wire across its surface until you get your desired shape or size. You don’t have to worry about digging into or tearing apart your project!

Foam cutters are powerful tools used for cutting and sculpting foam. They rely on the power of electricity to heat up a wire or an element to very high temperatures, and when it comes into contact with the foam, melts or burns through it. The tool is great for shaping and cutting intricate designs in blocks of foam as well as large sheets of foam without leaving any jagged edges or rough surfaces behind.

The most common type of foam cutter is a hot wire cutter. This uses an electrically heated wire to cut through the material instead of blades or saws. The size, shape, and thickness of the wire can vary depending on the project, but all hot wires reach extremely high temperatures that make them perfect for making precise cuts in foam.

Other types of foam cutters include water jet cutters which use pressurized jets of water combined with abrasive particles to cut through materials such as rubber and plastic. Laser engravers work similarly by using a laser beam that quickly heats up the material it comes into contact with, melting away any excess material as it passes over it.

-

How to maintain Foam Cutter

Foam cutter blades are essential tools for any foam cutting project. Taking regular care of them will ensure their longevity and effectiveness in the long run. Here are some tips on how to maintain foam cutter blades:

1. Clean the blade regularly – Make sure to clean the blade after each use with a soft cloth and mild soap solution. This will help remove any residue that may have accumulated on the blade during use, thus avoiding any build-up of material that can limit its effectiveness over time.

2. Sharpen the blade – Sharpening your foam cutter blades regularly is important in order to keep them effective and safe to use. You can either sharpen them manually or buy a sharpening tool specifically designed for foam cutter blades.

3. Lubricate the blade – Applying lubricant such as WD-40 or silicone spray helps keep your blades from rusting and wearing down over time, thus making sure they stay sharper longer and perform better when used for cutting foam materials.

4. Store your blades properly – Make sure to store your blades properly in a dry place away from sunlight so as to avoid corrosion or any other damage that could be caused by humidity or temperature changes over

Foam cutting is an important step in many industries and it is critical to maintain your foam cutter in order to ensure that it produces the best results. Here are some tips on how to make sure your foam cutter is working properly.

First, inspect the blades regularly and replace them when they start to dull or become damaged. This will help you get a more precise cut each time and reduce the risk of any unexpected accidents.

Second, make sure you properly clean the foam cutter after each use. This will keep dirt, dust, and other debris from accumulating on the blades and damaging them over time.

Third, lubricate all moving parts with a light oil or lubricant every few months so that they move smoothly when cutting through foam materials. This will also help keep your machine running longer without any breakdowns or issues.

Finally, store your foam cutter in a cool, dry place that is away from direct sunlight or extreme temperatures that could cause damage to its components over time. Taking these steps will help keep your foam cutter working efficiently for years to come!

-

Features of Foam Cutter

There are a variety of foam cutting solutions available on the market today, but none offer the versatility, safety, and convenience of a foam cutter. Foam cutters are specifically designed for cutting through foam materials with ease and precision. Here are some of the key features that make foam cutters so unique:

1. Cutting Efficiency - Foam cutters feature specialized blades that can easily slice through foam quickly and safely. This makes them ideal for any cutting job, no matter how small or large it is.

2. Safety - Foam cutters come with built-in safety features to help protect users from potential hazards while using the tool. This includes safety guards, anti-slip grips, and even an emergency stop button in case something goes awry during use.

3. Versatility - Foam cutters can be used for a variety of tasks such as carving intricate designs into foam material or simply trimming excess material away from a project’s edges. The adjustable guide rails ensure precise cuts every time while still allowing plenty of room to customize shapes and sizes as needed.

4. Portability - Most foam cutters are lightweight and easily portable, making them perfect for taking with you.

Foam cutters are incredibly versatile tools that allow you to easily and accurately cut through foam materials with ease. Foam cutters use a heated wire to smoothly and precisely slice through foam, allowing users to make intricate designs and shapes out of their material. Here are some of the features that make foam cutters such an invaluable tool:

- Precise Cuts: Foam cutter blades heat up quickly and evenly, allowing for precise cuts in any shape or size. The blades are designed to cut cleanly and consistently, giving you perfect results every time.

- Durability: Foam cutter blades are made from durable materials such as stainless steel or tungsten carbide, so they can handle tough cutting jobs without breaking or becoming damaged. Plus, they’re designed to last for a long time with minimal maintenance.

- Versatility: Foam cutter blades are used for a variety of different applications, from model making to upholstery work. They can even be used for intricate carving projects!

- Safety: Foam cutter blades feature an integrated safety switch that helps prevent accidental operation or overheating.