About the application of eps hot melting machine

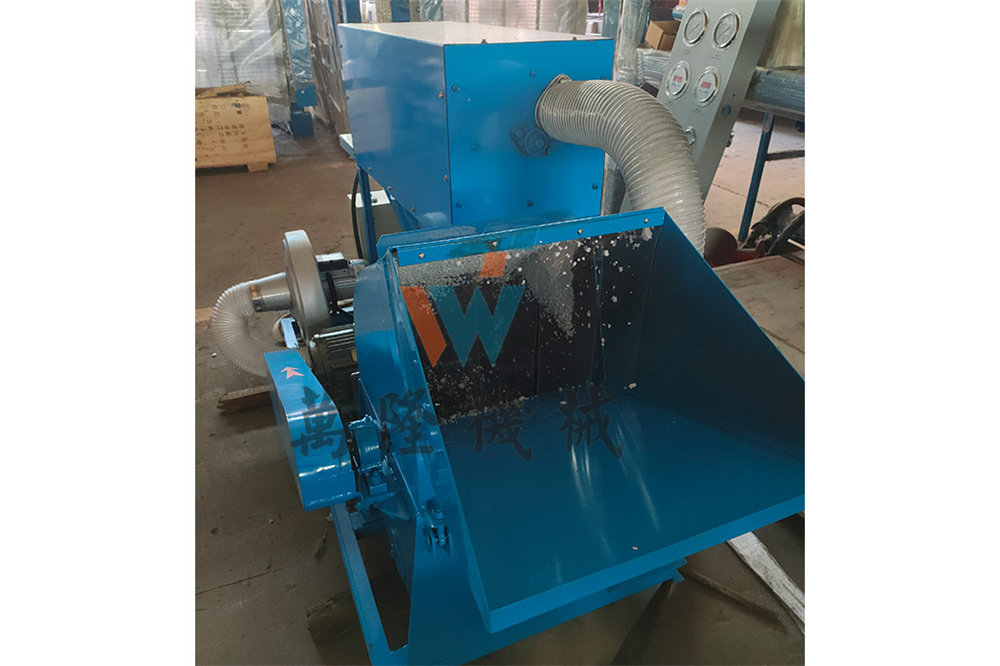

EPS hot melting technology is a new type of hot-melt adhesive equipment, which uses EPS as raw material to produce hot-melt adhesive. The equipment is simple in structure, easy to operate, and can be used for a long time without maintenance. It is an ideal equipment for enterprises to produce hot-melt adhesives.

EPS hot melting machine is mainly used in the field of building insulation and sound insulation. EPS material has the characteristics of light weight, good heat insulation, good water resistance and easy construction. It is an ideal thermal insulation material for buildings. The eps hot melting machine uses hot air to melt the EPS beads, and then uses high-pressure spraying equipment to spray the melted material onto the surface of the object to be insulated.

EPS hot melting machines are used in many different industries for a variety of purposes. For example, they are commonly used in the packaging industry for sealing and bonding products together. They can also be used in the construction industry for insulation and soundproofing. Additionally, EPS hot melting machines can be used for hobbies and crafts, such as making foam sculptures.

How to maintain eps hot melting machine

Here are some tips on how to maintain your eps hot melting machine:

- Keep the machine clean. Regularly clean the machine, both inside and out, to prevent dirt and dust build-up.

- Check the temperature. Make sure that the machine is set to the correct temperature for the material you’re using.

- Inspect the parts. regularly check for wear and tear on all parts of the machine, including the heating elements, pump, and hose.

- Use the proper materials. Only use materials that are compatible with your machine to prevent damage.

The eps hot melting machine is a kind of environmental protection equipment which can be used for a long time with proper maintenance. Here are some tips for you:

- Keep the surface of the machine clean and dry, so as to avoid rust and other problems.

- Check the tightness of each screw regularly and tighten it in time to prevent loosening.

- Check the work status of each component regularly, and if any abnormality is found, repair or replace it in time.

- The oil in the oil cup should be changed regularly to ensure the normal operation of the machine.

Common problems and solutions of eps hot melting machine

1. How to prevent clogging of EPS hot melting machine?

The material in the EPS hot melting machine should be stirred frequently to prevent the material from being too dense and causing clogging.

2. Why is the output of EPS hot melting machine low?

There are two reasons: first, the heating temperature is not high enough; second, the screw speed is too low. You can solve this problem by adjusting the heating temperature and screw speed.

3. Why does the EPS hot-melt machine smell bad?

The main reason is that there is something wrong with the raw materials you use, so you need to check the raw materials carefully.

Here are some common problems and solutions of EPS hot melting machines:

1. Problem: The machine doesn’t work at all or doesn’t work properly.

Solution: Check if the power supply is turned on and if the fuse is blown. If so, replace the fuse. If the problem persists, contact the manufacturer or a qualified technician.

2. Problem: The melting chamber is not hot enough.

Solution: Check the temperature setting and make sure it’s set correctly. If it is, then check for blockages in the heating elements or cooling fans. If there are none, then contact the manufacturer or a qualified technician.

3. Problem: The melting chamber is too hot. Solution: Check the temperature setting and make sure it’s set correctly. If it is, then check for blockages in the cooling fans. If there are none, then contact the manufacturer or a qualified technician