-

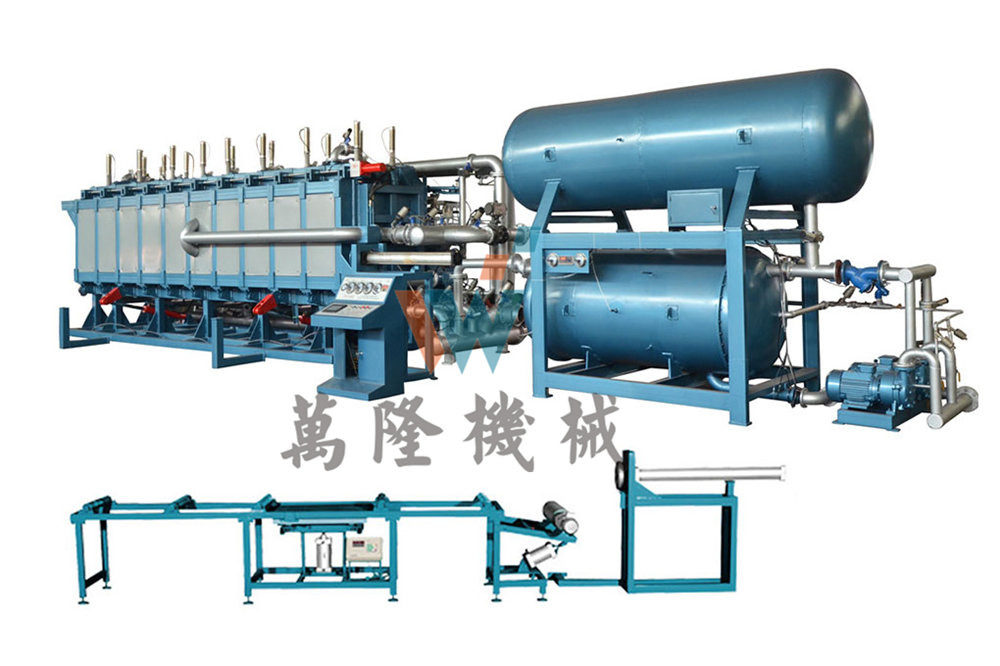

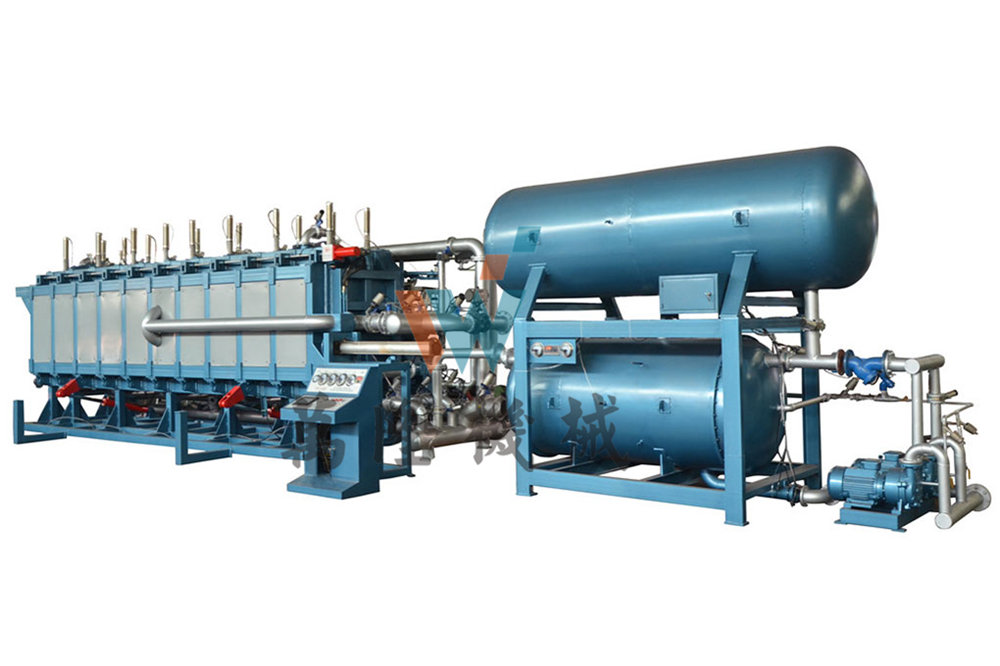

EPS vacuum block moulding machine

-

EPS polystyrene block moulding machine with adjustable template

-

Auto Block Moulding Machine with adjustable template

-

EPS polystyrene vacuum block moulding machine

-

EPS polystyrene foam beeds machine

Best Foam Cutter For Sale

The best foam cutter for sale is perfect for cutting through foam quickly and easily.

This cutter features a sharp blade that makes cutting through foam easy and fast.

The comfortable grip on the cutter makes it easy to hold and use.

The cutter is also lightweight, making it easy to move around.

The blade is also adjustable, so you can customize the cut to fit your needs.

Add To Basket

Add To Basket

PDF:

Best Foam Cutter For Sale

Product Descriptions

Best Foam Cutter For Sale

Foam cutters are a popular tool in the home improvement world. They are used to create intricate cuts into foam insulation, foam panels, and other materials. Foam cutters come in a variety of shapes and sizes, so they can be used for a variety of tasks. It is made out of a metal frame and a cutting blade. The device is attached to a power tool, such as a drill or a saw. The user attaches the foam cutter to the power tool and uses it to cut the foam.

With a foam cutter, you can quickly and easily make custom shapes out of foam. This tool is perfect for making models, prototypes, and decorations. You can also use it to create decorations for your home or office.

Choosing the right hot foam cutter can be a daunting task. With so many different varieties and prices, how do you know which one is right for you? Here are some factors to consider when shopping for a hot foam cutter.

1. Budget: The first factor to consider is your budget. Do you want a low-cost option or something that will last longer?

2. Size: Next, consider the size of the hot foam cutter.

Looking for a hot foam cutter that is both affordable and easy to use? Look no further than the Best Hot Foam Cutter For Sale. This machine is perfect for small businesses and home use, as it is very compact and easy to store. Additionally, this cutter offers great performance, making it a great choice for anyone looking for an affordable alternative to more expensive models.

About Foam Cutter

A foam cutter is a tool used to cut polystyrene foam and other types of foam. It is a handheld tool that uses a heated wire to melt the foam. Foam cutters are available in different sizes and shapes. The most common type of foam cutter is the hand-held cutter. It is also the most economical and easy to use.

A foam cutter is a tool used to cut polystyrene foam and other types of foam. It is often used for crafts projects, as well as for insulation and packaging. There are many different types of foam cutters available, but they all work in essentially the same way. A blade or wire is heated and then passed through the foam, cutting it cleanly.

Hot wire foam cutter

A hot wire foam cutter is a tool used to cut polystyrene foam. It consists of a thin metal wire that is heated by an electrical current and then passed through the foam. The heat from the wire melts the foam, allowing it to be cut into any shape. Hot wire foam cutters are commonly used in a variety of industries, such as advertising, packaging, and construction.

A hot wire foam cutter is a tool used to cut polystyrene foam and other thermoplastic materials. The cutter consists of a thin metal wire, often made of nichrome or stainless steel, that is heated to high temperatures using an electrical current. The wire is then passed through the foam, cutting it cleanly and smoothly. Hot wire foam cutters are often used in prototyping and model making, as they allow for clean, precise cuts with little effort.

Advantages of Foam Cutter

Perfect for cutting foam board, styrofoam, EPS foam, and more

Easily cuts through thick foam with little effort

Blades are made of high quality steel for durability

Adjustable cutting depth for precise cuts

Ergonomic handle for comfortable use

Foam Board Cutter

Are you looking for an affordable way to cut foam board? If so, the foam board cutter is for you! This simple tool can be used to make precise cuts in foam board, which makes it perfect for creating custom decorations or models. Plus, it's easy to use and can be tucked away when not in use. So what are you waiting for? Get your foam board cutter today!

A foam board cutter is a handy tool to have in your toolbox if you're ever needing to cut foam boards. It's a small, handheld saw that uses a small blade to make precise cuts. Because it's so small and portable, it's perfect for when you don't have access to a larger saw or when you need to cut smaller pieces of foam board.

The most important factor to consider when choosing a foam board cutter is the blade type. There are three main types of blades used in foam board cutters: straight edge, serrated edge, and chipper/shredder blades.

Eps Foam Cutting Machine manufacturer/supplier/factory in China

EPS foam cutting machines are designed for the production of precision parts from EPS foam. They have a variety of features that make them well-suited for a wide range of applications, including furniture and components, medical devices, and aircraft parts. The machines are easy to use and can produce accurate cuts quickly and easily.

Looking for a reliable and affordable foam cutting machine manufacturer supplier factory in China? Look no further than Eps. Our machines are known for their quality and accuracy, and our factory is located in the heart of China's manufacturing sector. Contact us today to learn more about our products and services.

Eps foam cutting machines are a popular choice for manufacturing due to their reliability and high-quality output. They are available from a variety of manufacturers, so finding the right one for your needs is easy. If you're looking for a reliable supplier, China is the place to be.

| Item | Unit | PSQ300 | PSQ600 | Multifunctional |

|---|---|---|---|---|

| Max Size of productive | mm | 3000*1250*1250 | 6000*1250*1250 | 6000*1250*1250 |

| Transfomer Capacity | kva | 5.2 | 5.2 | 15 |

| Total Power of stalled Machine | kw | 6.55 | 6.55 | 17.45 |

| Max Extemal Dimensions | mm | 5800*1900*2480 | 8800*1900*2480 | 8800*1900*2480 |

| Stalled Weight | kg | 1200 | 1800 | 2800 |